The 6-Minute Rule for Laser Scanning Solutions, Llc.

Table of ContentsWhat Does Laser Scanning Solutions, Llc. Mean?Not known Incorrect Statements About Laser Scanning Solutions, Llc. The Best Strategy To Use For Laser Scanning Solutions, Llc.Not known Details About Laser Scanning Solutions, Llc.

In order to place a laser light beam in two dimensions, it is possible either to revolve one mirror along 2 axes - used primarily for slow-moving scanning systems - or to mirror the laser beam of light onto two carefully spaced mirrors that are mounted on orthogonal axes (https://on.soundcloud.com/gQF2n). Each of the two flat or polygon (polygonal) mirrors is after that driven by a galvanometer or by an electrical motor specifically

Some applications need placing the emphasis of a laser beam in 3 dimensions. This is achieved by a servo-controlled lens system, typically called a 'focus shifter' or 'z-shifter'. Lots of laser scanners better allow altering the laser strength. In laser projectors for laser television or laser screens, the 3 basic colors - red, blue, and environment-friendly - are integrated in a single beam and after that shown along with 2 mirrors.

Modern lasers can cut steel blocks with a thickness of 10 cm and even more or ablate a layer of the cornea that is only a couple of micrometers thick. The capability of lasers to solidify fluid polymers, along with laser scanners, is made use of in rapid prototyping, the capacity to melt polymers and steels is, with laser scanners, to create components by laser sintering or laser melting.

Laser Scanning Solutions, Llc. - An Overview

That card converts the received vector information to movement information which is sent to the scanhead. This scanhead includes 2 mirrors that are able to deflect the laser beam in one level (X- and Y-coordinate). The third measurement is - if required - understood by a certain optic that has the ability to move the laser's centerpiece in the depth-direction (Z-axis).

For these cases it is essential that the laser has as small a centerpiece as feasible (3d laser scanning services). For enhanced laser scanning applications and/or high product throughput during production, scanning systems with greater than one scanhead are used. Below the software program needs to control what is done precisely within such a multihead application: it is feasible that all readily available heads have to note the same to complete handling faster or that the heads note one single work in parallel where every scanhead carries out a component of the work in instance of huge workspace

In these tools, a semiconductor laser beam is usually scanned with the help of a resonant mirror scanner. The mirror is driven electromagnetically and is made from a metal-coated polymer. When a space copyright has to dock to the spaceport station, it should meticulously maneuver to the proper position. In order to determine its family member placement to the spaceport station, laser scanners constructed right into the front of the space copyright check the form of the room station and after that establish, with a computer, the steering commands.

The uses simply noted which are just a small sampling of laser scanning applications have extensively varying technical demands. This consists of specifications like scanning rate, the dimension of the area or volume that must be covered, the laser power look at this web-site included, the price, size, dependability, and life time of the scanner, and a lot more.

Rumored Buzz on Laser Scanning Solutions, Llc.

Depending on the nature of the job, galvanometer scanners are typically utilized in sets. This enables the laser light beam to reach any factor in an airplane.

Going back to 1960, when Theodore Maiman developed the very first laser, this type of light has advanced right into a tool utilized throughout sectors. From clinical treatment to manufacturing processing, the power of lasers is utilized throughout a myriad of sectors and for lots of kinds of applications. When most think of lasers, the ubiquitous red light lasers often enter your mind.

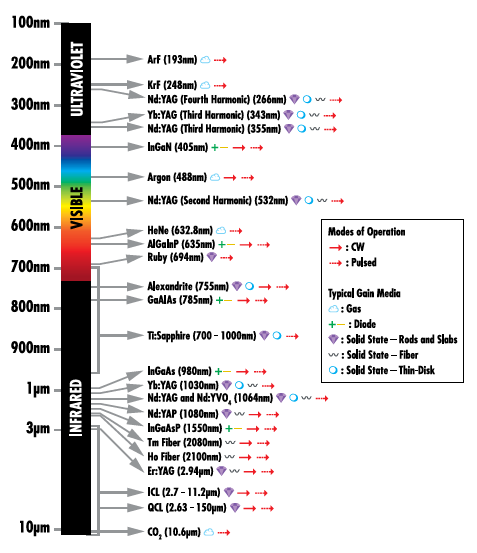

There are over eight kinds of lasers across 3 classifications! Light wavelength circulation map Solid-state lasers are kinds of lasers that use a strong product as its gain medium.

The Of Laser Scanning Solutions, Llc.

When a laser diode beams light on the drugged product, the neodymium atoms are thrilled and produce light. This light is after that enhanced by the product and emitted as a laser beam of light.

Gas lasers are utilized for machining and noting applications like noting tags, etching plastic and materials, processing, and cutting. These laser kinds use gas as the medium rather than a solid or liquid. The 4 kinds of gas lasers are carbon dioxide, He-Ne, excimer, and argon. Carbon dioxide gas lasers have the longest wavelength contrasted to fiber, YAG, and YVO4.

As a result of the long wavelength, there is more warm transfer than various other lasers. CO2 lasers are typically utilized for cutting products. He-Ne gas lasers have a wavelength of 630 nm and show up red to the human eye. He-Ne lasers are commonly recognized for their usage as pointing devices in classrooms or throughout presentations.